Intelligent Coating System C3-P (High end Type)

Equipment performance

1. The overall design adopts a steel structure, which can withstand the impact during high-speed operation, and the machine runs smoothly without resonance noise;

2. Using an industrial computer with a motion control card and WINDOWS 7 operating system;

3. Adopt manual teaching and CAD mapping programming mode, with fault sound and light alarm and menu warning;

4. The three-axis transmission platform adopts a precision ball screw transmission system combined with Panasonic servo motors;

5. Equipped with 2 rubber valves, the needle type rubber valve can be equipped with a needle calibration device;

6. The Z-axis direction can automatically raise and lower the glue valve according to the height of the irregular component to adjust the height of a single coating;

7. It can achieve coating and dispensing of straight lines, circles, arcs;

8. Equipped with a set of dedicated paint storage tanks, sealed and continuously supplied, ensuring even and consistent feeding;

9. The machine is equipped with a dedicated cleaning device, an independent cleaning solution container, and can automatically clean the rubber valve;

10. Can be equipped with exhaust gas collection and emission devices; Built in filter, exhaust emissions can meet environmental standards

11. Equipped with SMEMA signal port, it can be connected online with other devices;

12. The high-precision DC brushless motor is equipped with a stainless steel extended chain, which can smoothly transport the product to the designated position quickly, stably, and accurately, without causing product damage.

13. Equipped with control buttons to achieve functions such as "emergency stop"

14. Equipped with a front door alarm system that stops working when the door is opened;

15. Quality traceability system: The equipment has QR code and barcode scanning functions, which can record product information based on barcodes.

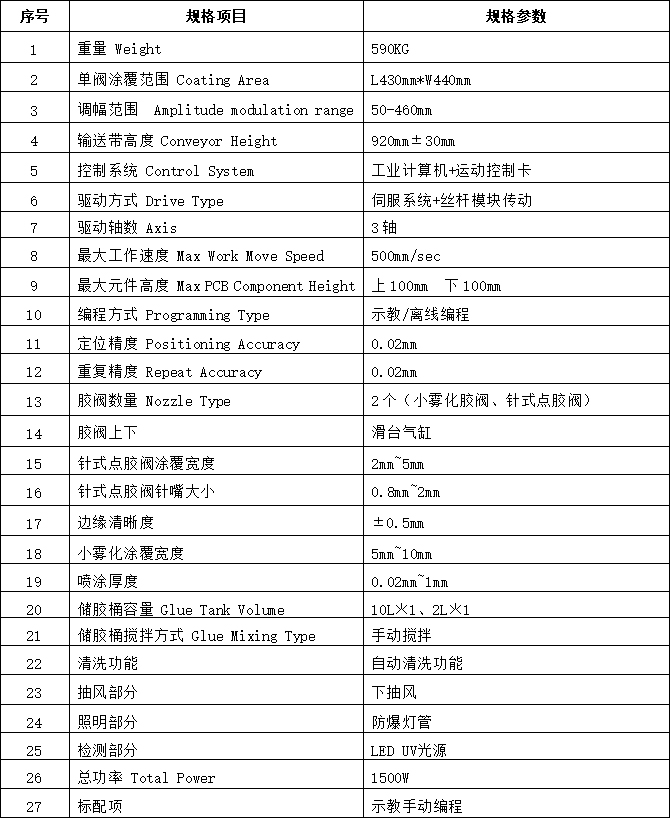

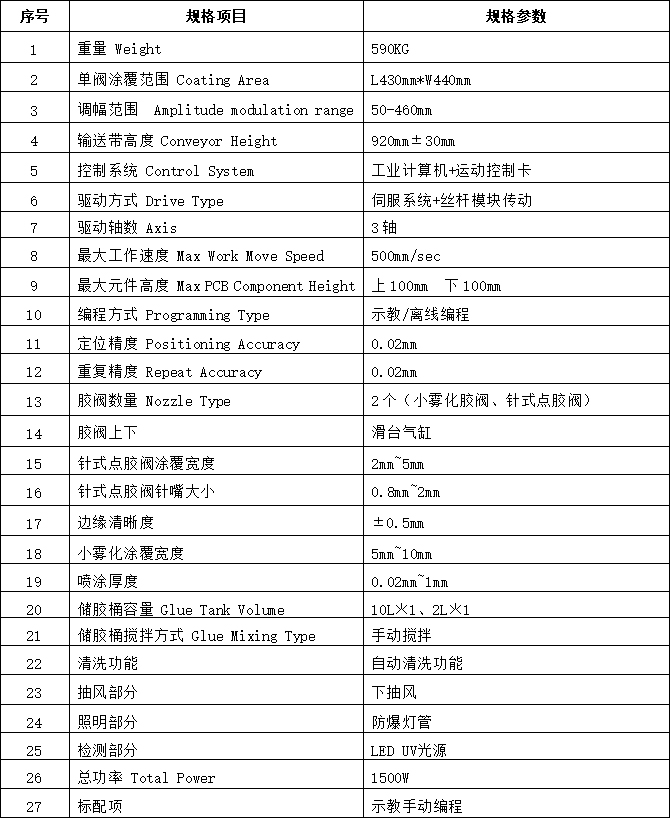

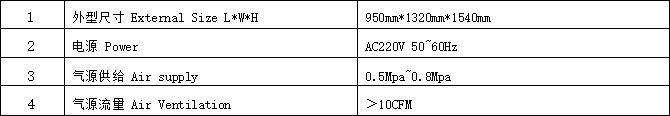

Technical parameters:

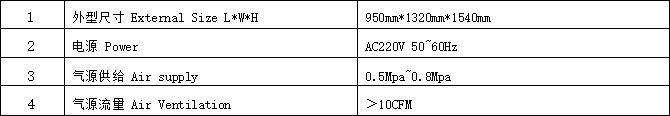

Factory requirements:

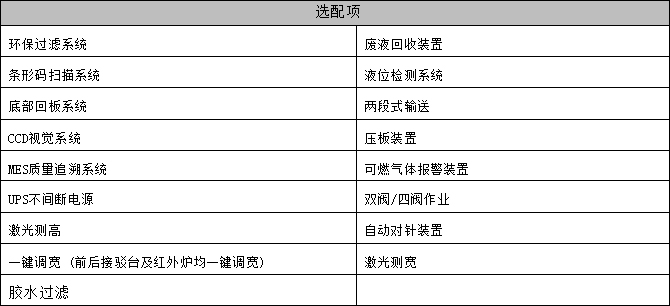

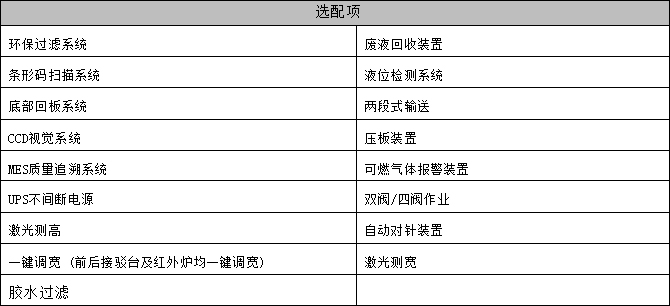

Configuration Description:

Configuration Description: