Performance characteristics:

1. Shell: made of T1.5mm steel plate. Bottom bracket: made of welded steel pipes;

2. Bottom bracket: made of welded steel pipes;

3. Fixed auxiliary equipment: Use foot cups with rubber pads to support the body;

4. Bracket sealing plate: using cold plate hydraulic precision machining to form, single-sided rapid prototyping, and computer white RAL9003 baking paint;

5. Insulation layer: filled with aluminum silicate high-temperature resistant cotton, with an effective thickness of 40mm;

6. Heating tube: Use a hot air heating tube with a total power of 14.5KW, evenly installed, and the equipment is divided into 6 temperature zones;

7. Install 6 motors on the top for air transportation, with adjustable speed;

8. Transport direction: left right or right left (optional);

9. Conveyor guide rail: using self-developed specialized aluminum guide rail, surface hardened treatment, double-sided synchronous installation, total length 3000mm;

10. Rail adjuster: Use one set of 4-inch adjustment handwheels and three sets of galvanized fixed seats for 6-point synchronous adjustment, effectively widening the track by 50-450mm;

11. Conveyor chain: Use a 2-point belt with a 5mm extended pin roller conveyor chain, embedded with aluminum guide rails, and equipped with galvanized synchronous transmission wheels;

12. Drive motor: using electronic speed regulation motor, with adjustable speed;

13. Furnace cover opening method: Electric lifting, with limit protection function for easy operation.

14. PLC+touch screen control, the air handling fan is adjusted through a frequency converter.

15. It can be equipped with a standard SMEMA signal port and can be connected to other devices online.

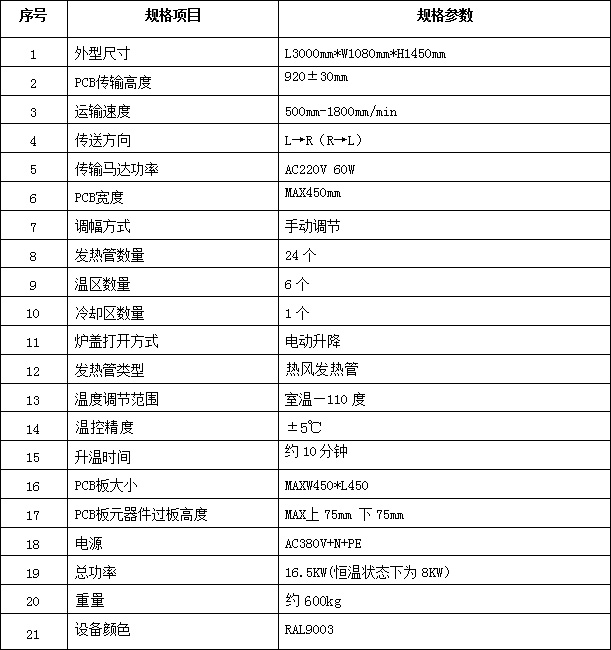

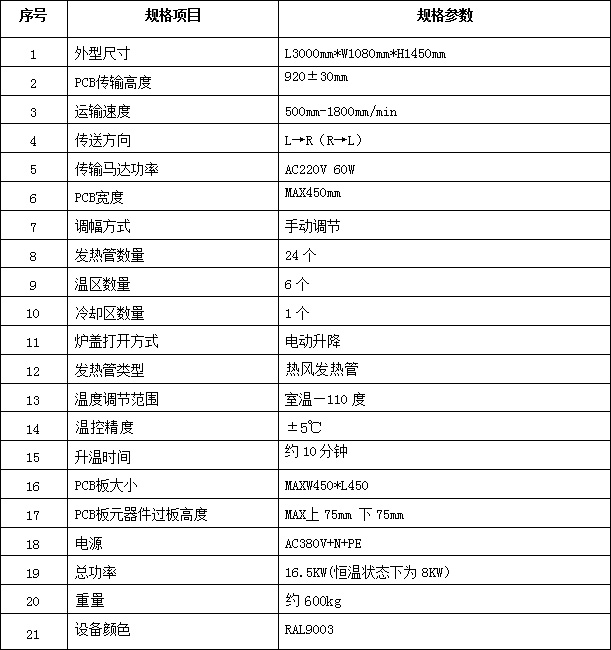

Technical parameters: