Performance characteristics:

1. It is mainly used at the source of the coating production line to store and transport PCB boards through the material frame to the backend equipment, with automatic board feeding function.

2. The control system adopts PLC control, and the operation interface adopts touch screen, with stable performance and convenient operation;

3. The rack structure adopts sheet metal welding, aluminum profile construction, and surface painting treatment;

4. The lifting structure adopts a motor lifting setting, with effective step sizes of 10mm, 20mm, 30mm, and 40mm, and an optional frequency converter can be added;

5. The board delivery method adopts a cylinder type, which can be equipped with an automatic air release device to ensure that the PCB will not be damaged and reduce process losses;

6. The frame in method adopts bottom in and top out, effectively shortening the frame changing time;

7. Equipped with standard SMEMA signal port, it can be connected online with any other device;

8. Anti static covers and L-shaped feeding machines can be installed as needed.

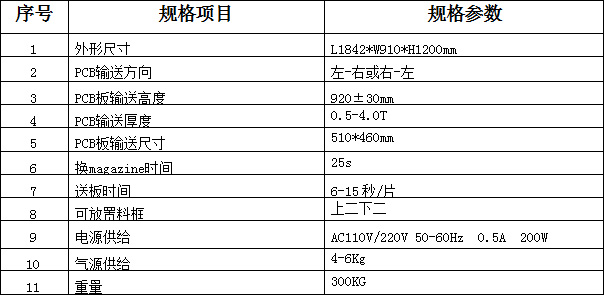

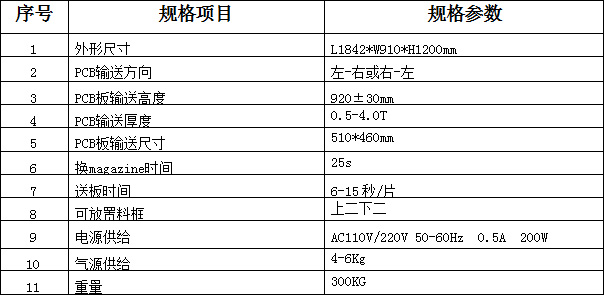

Technical parameters: