Equipment Introduction

1. The overall color scheme adopts industrial gray and computer white as the main colors, which are coordinated with the on-site equipment used by the customer.

2. Install two three color lights at the top diagonal position to ensure that the equipment operation status can be observed from any position in the workshop

3. Adopting PC control PLC, the display screen and overall operation surface are integrated into one. Can be connected to customer MES SF and other systems to transmit real-time temperature equipment status and other data.

4. The internal structure adopts a steel frame to ensure stability and reliability.

5. Independent control for rise and fall, using closed-loop motor and precision reducer to ensure the repeatability accuracy of the lifting position.

6. Four point width adjustment mechanism ensures stable width adjustment and avoids track horn mouth

7. Maximum board width min100X100mm max410X420mm

8. The independently developed air duct system ensures uniform air outlet temperature and stable air outlet direction.

9. Use LC self-made and repeatedly tested heating wires to ensure stable heating temperature.

10. The motion control and temperature control adopt Panasonic's motion control module and temperature control module to ensure the accuracy of position control and the stability of temperature control.

11. The hot air motor adopts Schneider+LC customized high-temperature motor to ensure stable wind speed.

12. A second set of temperature inspection instruments independent of the temperature control system, with multiple protection controls for temperature.

Product parameters:

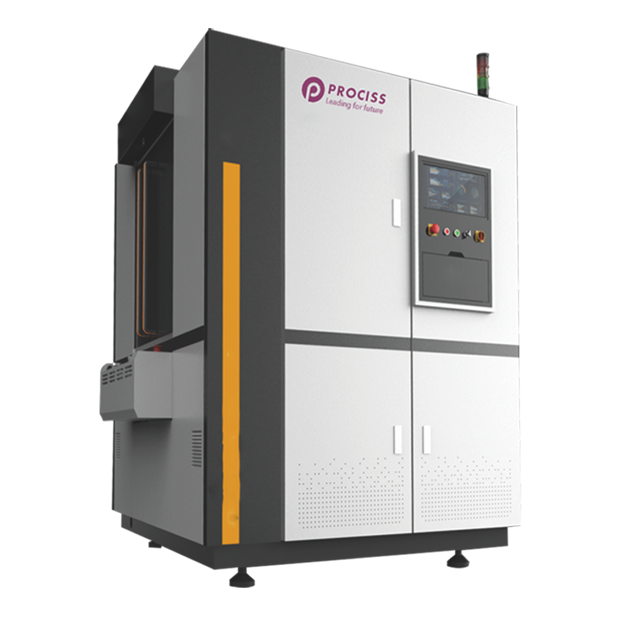

Appearance drawing:

Appearance drawing:

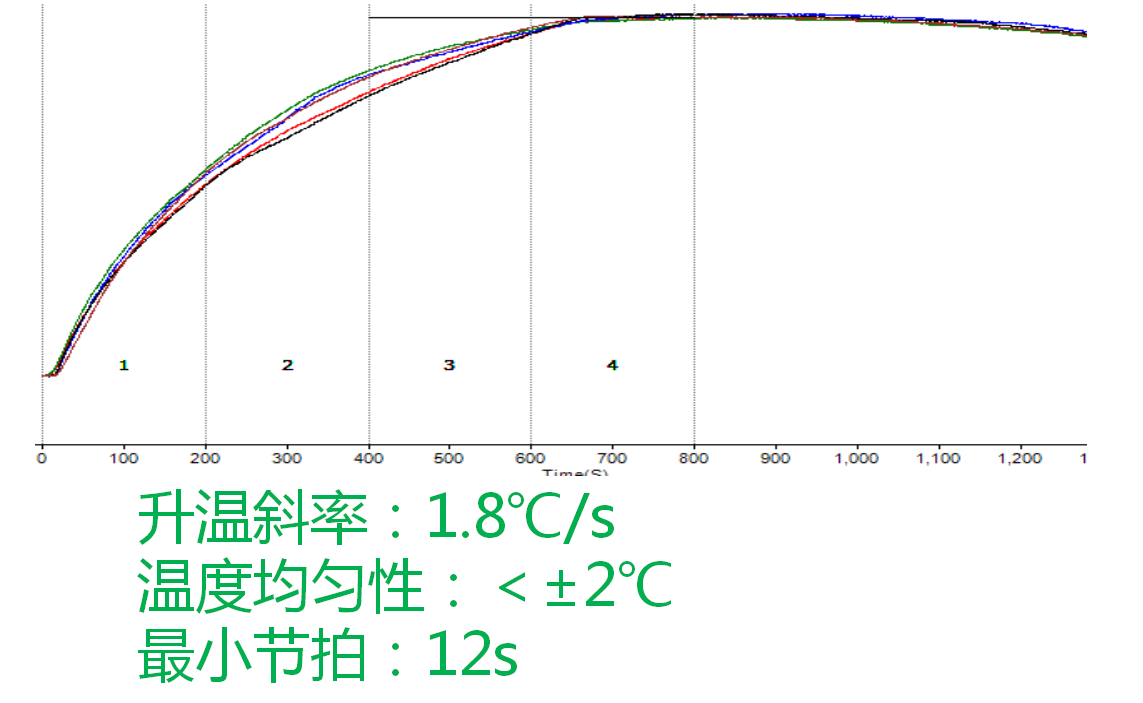

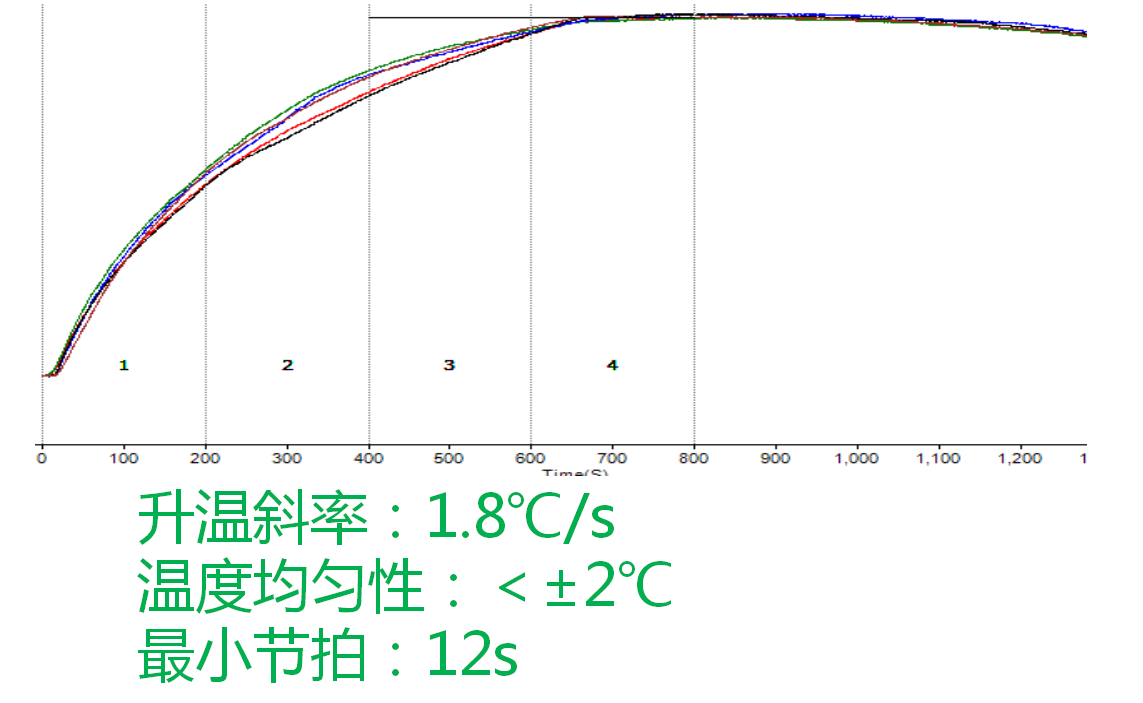

Temperature curve:

Temperature curve: