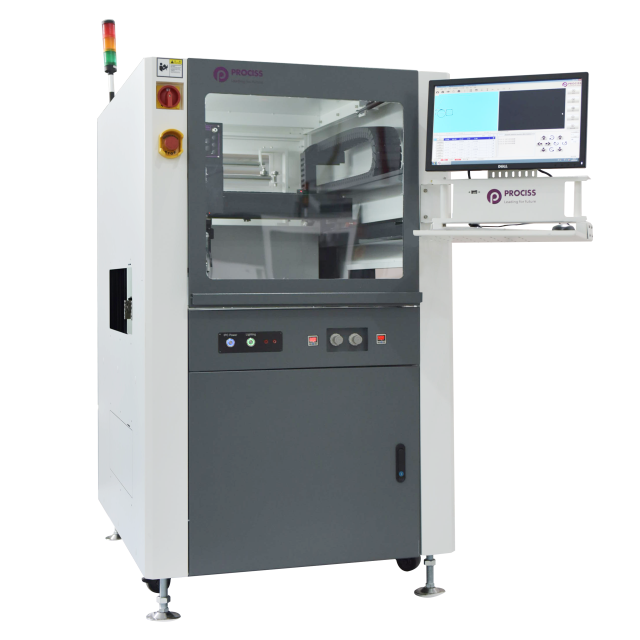

Welcome to Prociss!

|

1 |

External Size L*W*H |

1050mm*1320mm*1540mm |

|

2 |

Power |

AC220V 50~60Hz |

|

3 |

Air supply |

0.5Mpa~0.8Mpa |

|

4 |

Air Ventilation |

>10CFM |

Configuration Description:

|

Serial Number |

Specification content |

Specification parameters |

|

1 |

Weight |

make an appointment 650KG |

|

2 |

Deviation rotation single valve dispensing 5-axis

|

X500mm*Y500mm |

|

3 |

Amplitude modulation range |

50-550mm |

|

4 |

Conveyor Height |

920mm±30mm |

|

5 |

Maximum load on the track |

|

|

6 |

Control System |

Industrial computer+motion control card |

|

7 |

Drive Type |

Servo system+screw module transmission |

|

8 |

Max Work Move Speed |

500mm/sec |

|

9 |

Max PCB Component Height |

上80mm 下80mm |

|

10 |

Programming Type |

Teaching manual programming |

|

11 |

Rotation Angle |

170° |

|

12 |

Rotation Angle |

±60° within |

|

13 |

Positioning Accuracy |

0.025mm |

|

14 |

Repeat Accuracy |

0.025mm |

|

15 |

Nozzle Type |

1 (Select high-pressure valve based on adhesive viscosity) |

|

16 |

Rubber valve up and down |

Z Axis lifting |

|

17 |

Glue Tank Volume |

According to the adhesive packaging (optional) |

|

18 |

Lighting section |

Explosion proof lamp tube |

|

19 |

Total Power |

1500W |

|

20 |

Standard configuration items |

Teaching manual programming |

|

Rubber valve optional items |

|

|

High pressure silicone valve (PS-507HV) Quantity: |

|

|

Optional options for adhesive supply method |

|

|

Single barrel (2600CC) screw glue supply pump |

Single barrel (300CC) pneumatic glue supply pump |

|

Single barrel (2600CC) pneumatic glue supply pump |

Single barrel (300CC) screw glue supply pump |

|

Double barrel (300CC) screw glue supply pump |

|

|

Function optional items |

|

|

Automatic weighing system (reading accuracy 0 1mg)¨ |

Laser height measurement |

|

CCD vision system (visual programming correction and error prevention self-test) |

XYZ Multi dimensional Needle Calibration System |

|

MES Quality Traceability System |

|

|

Needle height correction device |

Bottom return plate device |

|

Width Adjustment Type: Electric Width Adjustment, Manual Width Adjustment, One Click Width Adjustment |

Liquid level detection

|

|

Needle cleaning device - Needle cleaning - Flat mouth cleaning - Vacuum cleaning |

|