3C

Fingerprint recognition module adhesive assembly

1. Industry Introduction

2. Process characteristics

• Same as the world's leading fingerprint recognition technology

Reduce manual involvement and improve quality

A complete automation solution to enhance the company's image

• Production line operation to improve overall efficiency

Solution

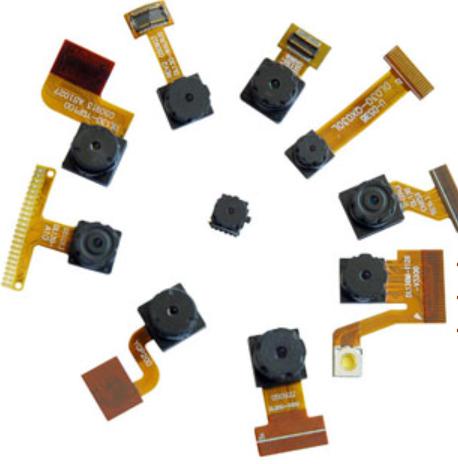

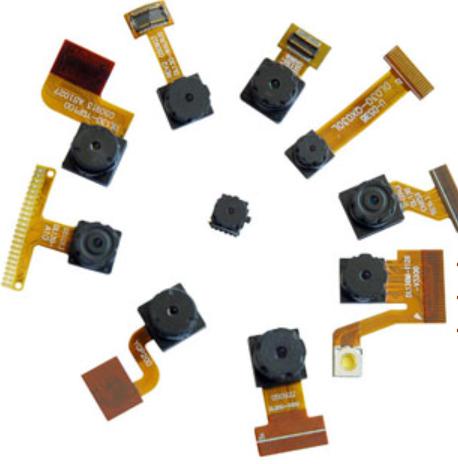

Camera module dispensing solution

1. Industry Introduction

The camera modules introduced in this application mainly include: front and rear cameras for mobile phones, front and rear cameras for tablets, laptop cameras, car cameras, and so on. In recent years, camera modules have developed rapidly, from low pixel to high pixel, from fixed focus to autofocus, and in the future, advanced features such as optical stabilization and 3D imaging will be added.

2. Process characteristics

The camera module mainly includes the following parts: FPC, SENSOR, LENS, VCM, etc. Its internal structure is complex and precise, and multiple components need to be assembled through glue, among which VCM assembly is more difficult. At present, camera modules on the market automatically point

The main difficulties in the adhesive dispensing process are as follows:

The components are too small for traditional dispensing equipment to meet the requirements;

High requirements for visual system recognition and localization capabilities;

The efficiency and yield of contact dispensing such as syringes are very low

Visual desktop robot PE441T+DS200

Solution for dispensing electroacoustic components

1. Industry Introduction

Electroacoustic devices are essential components for people to transmit information and spread culture and art through sound. They have functions such as receiving, converting, transmitting, reproducing, and measuring sound. Electroacoustic devices mainly refer to speakers, speaker systems, microphones, headphones, earphones, receivers, transmitters, receiver groups, various communication caps and pickups, as well as related accessories.

2. Process characteristics

The main structure of electroacoustic devices is similar, consisting of coils, vibrating membranes, magnets, and external structural components, which require a large amount of adhesive technology in the production and assembly process of these components. With the development of electronic components, there are higher requirements for the dispensing of corresponding parts, and the dispensing process also needs to be more intelligent, able to automatically identify the dispensing position and monitor the dispensing process.

The main difficulties in the dispensing process of electroacoustic devices are:

• Refinement of dispensing positions;

The dispensing position needs to be able to be automatically identified;

Consistency and repeatability of the dispensing process.

Visual desktop robot PE441T+syringe/valve

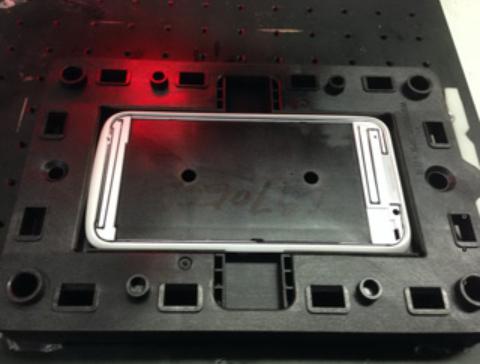

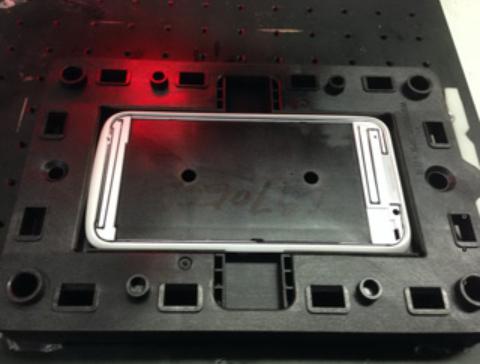

Adhesive bonding of phone frame

1. Industry Introduction

In the production and assembly process of mobile phones, border bonding is an important step. The traditional production process mainly uses fast drying glue, tape and other bonding methods, which can easily lead to problems such as insufficient bonding strength and poor sealing performance. The PUR hot melt adhesive used for mobile phone frames has the characteristics of fast curing speed, high bonding strength, and good sealing performance, thus quickly replacing traditional bonding processes and becoming the mainstream production process at present.

2. Process characteristics

With the development of the mobile phone industry, in order to achieve a larger screen to body ratio, the bezels of mobile phones are becoming narrower, and higher requirements are being put forward for the assembly of phones with narrow bezels.

At present, the bonding of mobile phone borders mainly uses standard packaged hot melt adhesive. The main difficulties in producing narrow border mobile phones are:

Ultra fine line width requirements;

• Uniformity and consistency of lines;

The rubber strip is prone to breakage, wire drawing, and other issues.

3. Solution

Recommended configuration: PE441T+hot melt adhesive system

Optional: Laser height measurement, needle calibration

1. Industry Introduction

2. Process characteristics

• Same as the world's leading fingerprint recognition technology

Reduce manual involvement and improve quality

A complete automation solution to enhance the company's image

• Production line operation to improve overall efficiency

Solution

Camera module dispensing solution

1. Industry Introduction

The camera modules introduced in this application mainly include: front and rear cameras for mobile phones, front and rear cameras for tablets, laptop cameras, car cameras, and so on. In recent years, camera modules have developed rapidly, from low pixel to high pixel, from fixed focus to autofocus, and in the future, advanced features such as optical stabilization and 3D imaging will be added.

2. Process characteristics

The camera module mainly includes the following parts: FPC, SENSOR, LENS, VCM, etc. Its internal structure is complex and precise, and multiple components need to be assembled through glue, among which VCM assembly is more difficult. At present, camera modules on the market automatically point

The main difficulties in the adhesive dispensing process are as follows:

The components are too small for traditional dispensing equipment to meet the requirements;

High requirements for visual system recognition and localization capabilities;

The efficiency and yield of contact dispensing such as syringes are very low

Visual desktop robot PE441T+DS200

Solution for dispensing electroacoustic components

1. Industry Introduction

Electroacoustic devices are essential components for people to transmit information and spread culture and art through sound. They have functions such as receiving, converting, transmitting, reproducing, and measuring sound. Electroacoustic devices mainly refer to speakers, speaker systems, microphones, headphones, earphones, receivers, transmitters, receiver groups, various communication caps and pickups, as well as related accessories.

2. Process characteristics

The main structure of electroacoustic devices is similar, consisting of coils, vibrating membranes, magnets, and external structural components, which require a large amount of adhesive technology in the production and assembly process of these components. With the development of electronic components, there are higher requirements for the dispensing of corresponding parts, and the dispensing process also needs to be more intelligent, able to automatically identify the dispensing position and monitor the dispensing process.

The main difficulties in the dispensing process of electroacoustic devices are:

• Refinement of dispensing positions;

The dispensing position needs to be able to be automatically identified;

Consistency and repeatability of the dispensing process.

Visual desktop robot PE441T+syringe/valve

Adhesive bonding of phone frame

1. Industry Introduction

In the production and assembly process of mobile phones, border bonding is an important step. The traditional production process mainly uses fast drying glue, tape and other bonding methods, which can easily lead to problems such as insufficient bonding strength and poor sealing performance. The PUR hot melt adhesive used for mobile phone frames has the characteristics of fast curing speed, high bonding strength, and good sealing performance, thus quickly replacing traditional bonding processes and becoming the mainstream production process at present.

2. Process characteristics

With the development of the mobile phone industry, in order to achieve a larger screen to body ratio, the bezels of mobile phones are becoming narrower, and higher requirements are being put forward for the assembly of phones with narrow bezels.

At present, the bonding of mobile phone borders mainly uses standard packaged hot melt adhesive. The main difficulties in producing narrow border mobile phones are:

Ultra fine line width requirements;

• Uniformity and consistency of lines;

The rubber strip is prone to breakage, wire drawing, and other issues.

3. Solution

Recommended configuration: PE441T+hot melt adhesive system

Optional: Laser height measurement, needle calibration

Technology leads the future • Professionalism creates brilliance

Follow Prociss WeChat for more information!

If you want to learn more information, join us!

Prociss (SuZhou)Intelligent Equipment Co.,Ltd.

Tel: +86-0512-66302804

Fax: +86-0512-67132005

Email:sales@prociss.com

Http:www.prociss.com

Add:No. 8 Mocheng Avenue, Hengxin New Energy Vehicle Industrial Park, Changshu, Suzhou City

Scan the QR code!

- Previous article:Elevator.

- Next article:Rail Transit